Services

We are committed to providing customers with comprehensive and efficient service solutions, tailor-made for you.

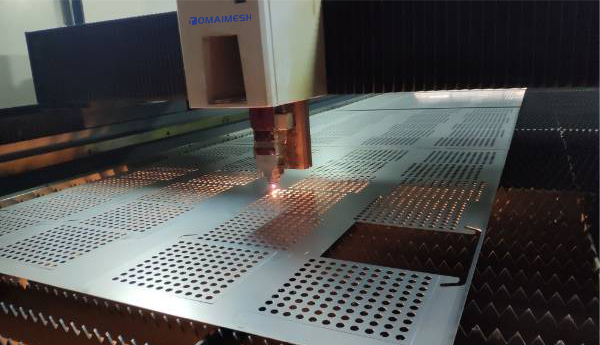

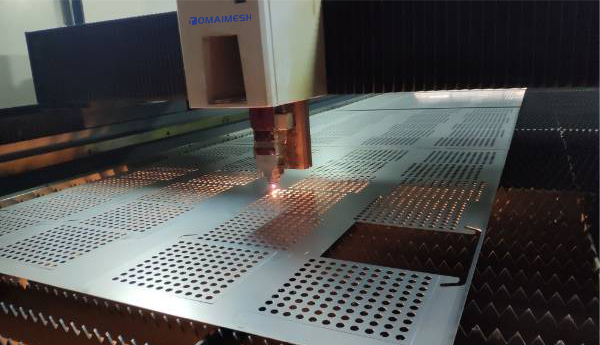

01.

Laser Cutting Cut To Size

We can quickly and accurately cut materials to the size you need. We have more than 50 metalworking machines, including high speed band saws, light and heavy duty shears, miter saws and other cutting tools. Whether you need a fixed length panel, sheet, plate or coil, TOMAIMESH meets your requirements. If your work requires miters, radius patterns, circles, grooves or other shapes, we can help!

02.

CNC Punching Process

There are many materials that CNC machines can press, such as stainless steel, galvanized steel, aluminum, copper and plastic. The automation and repeatability of CNC stamping makes the stamping process both accurate and fast, while generating less waste. Our commonly used CNC punching machines include ordinary CNC punching machines, gantry punching machines and turret punching machines. We'd be happy to introduce you.

Have Some Questions?

Choose us, give you stronger protection and higher value!

03.

Welding Process

Multiple welders are employed in each machining shop. Our welders are highly skilled and qualified. Many customers rely on TOMAIMESH to assemble and weld finished products, such as filter products and perforated plate products. Our welders are experts in the manufacture of steel, aluminum and stainless steel materials. They can also manufacture relevant accessories according to your specifications to match your products.

04.

Surface Treatment

TOMAIMESH has pre-galvanizing, hot-dip galvanizing or powder coating lines to provide metal surface treatment on request. To prevent corrosion and extend the service life of the product. For customers who like the appearance of the finished product, we can also anodize aluminum products and polish stainless steel products!

05.

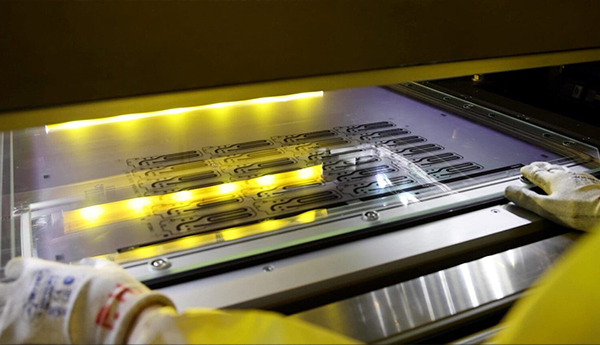

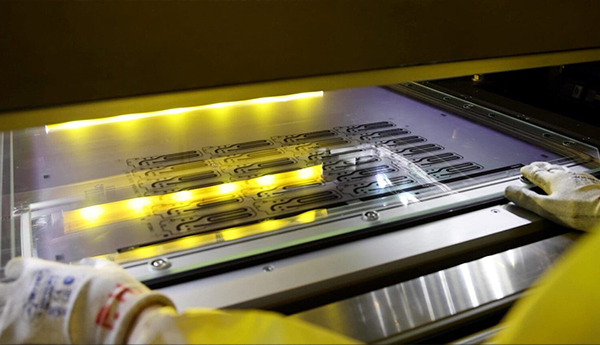

Chemical Etching

Chemical etching can be applied to almost any metal, regardless of its hardness or toughness. We process more than 100 tons of sheet metal per year, covering more than 2,000 metal types. This not only provides our customers with purchasing economics, but also ensures the ready availability of various metals in our inventory. Its precision, speed and unique properties are impossible to achieve with traditional sheet metal processing technology.

06.

CNC Bending

We have bending machine, using a pneumatic or hydraulic press brake, and a Laser bending machine, the thickness can be done up to 20mm, the widest size up to 6meters. We have experienced skilled workers and precise machines, and can absolutely guarantee the quality of your products.

Mechanical and hydraulic systems are controlled by computers and can achieve automation by using CAD/CAM drawings to improve efficiency and shorten delivery time, so that the bending plate has a more consistent and accurate size.

07.

Drawing Custom Design

We strive to exceed our customers' expectations, which often involves supporting the design process. Our structural detail experts and computer-aided design (CAD) experts can generate multidimensional views to help create, modify, analyze, or optimize your product design. Or directly use the drawings provided by customers to manufacture products. Welcome to email your product drawings to [email protected], we look forward to serving you!

08.

Packaging & Logistics

TOMAIMESH offers a full range of services such as custom packaging and transportation. Our staff will take great care to package your order and make sure it is delivered on time and by the method you choose. In view of the wide variety of pore product sizes and shapes available, we offer a variety of packaging customization solutions. TOMAIMESH's product managers are ready to discuss these options with you.

Yes, our company provides customized service. We can customize the processing according to the specific needs of customers. We can provide personalized solutions according to the size, aperture, material requirements and other special needs of our customers. Our technical team will ensure that customized products meet your requirements and provide professional design and manufacturing support.

The lead time of the product usually depends on the number of orders, complexity and whether custom processing is involved. Delivery times for standard products are generally 7-15 business days, while custom products can take longer, usually 15-30 business days. We will confirm the specific delivery time with you according to the order status and do our best to ensure timely delivery. If there is an urgent need, please contact us, we will arrange priority production according to your requirements.

Yes, we provide comprehensive after-sales service. Our after-sales team will assist with any problems encountered during the use of the product, including installation, use and maintenance. If you find quality problems or have any technical questions during use, please feel free to contact us, we will provide you with timely technical support and solutions. We are committed to ensuring customer satisfaction and providing you with long-term support.

We are more than happy to provide our customers with samples for testing. For standard products, you can request samples directly for testing to ensure that the product meets your needs. For custom products, we can provide small batch samples or preliminary designs for your review. After confirming the sample, we will further adjust and improve the product design based on your feedback. The cost and freight of the sample can be further discussed with our sales team.

Yes, all our products meet international quality standards. We strictly follow the ISO certification system and related industry standards for production and inspection to ensure that every product meets the high quality requirements.

Request a Quote

Get in touch with us now and book your appointment or get a free consultation for the issue you are facing.